Quality is rarely random - and therefore our claim

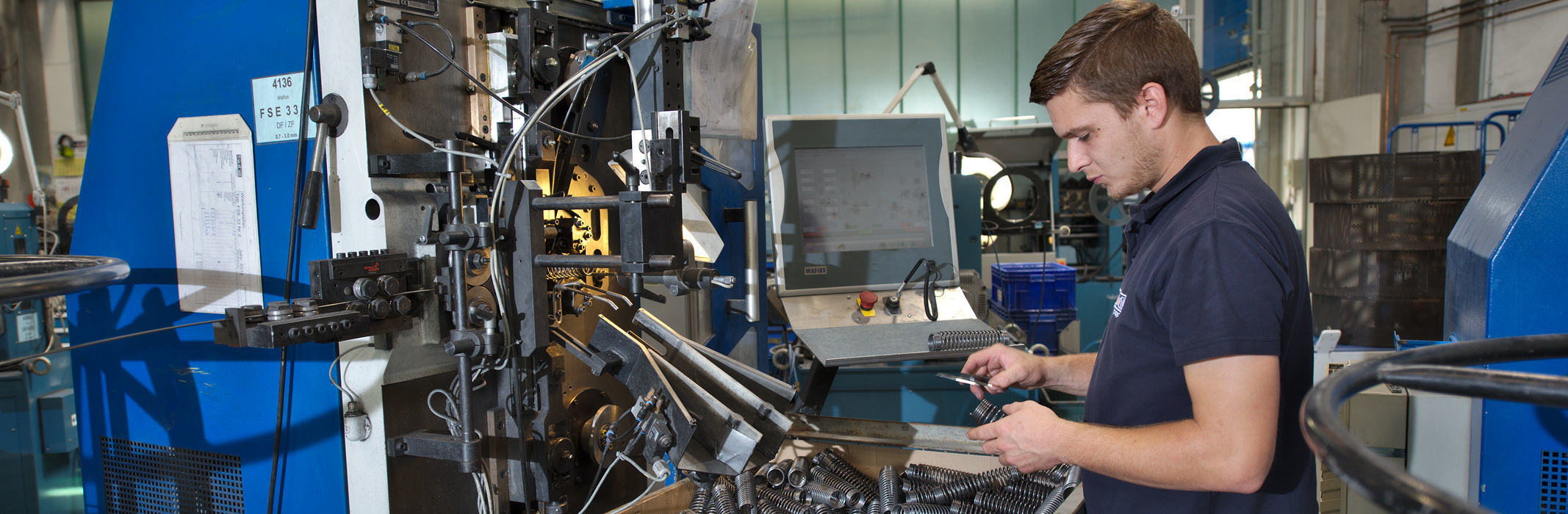

We test our products. And with systems, too.

Every day, we supply well-known companies throughout the world with millions of articles from our locations.

To guarantee the consistently high quality, the Subtil-Group has integrated a location-based comprehensive management system that encompasses quality, environment and safety.

The aim of this system is to have a documented way of determining that the requirements for products processes and that these are fulfilled, from inquiry to delivery. After all, ultimately, long-term business success is only ensured by a high level of customer satisfaction. Therefore, our system is lived by all employees every day.

Ensuring customer satisfaction includes:

- ERP supported scheduling for production and delivery

- Sampling according to customer requirements

- Consistent quality planning early in the project phase

- CAQ supported inspection planning from receiving to shipping

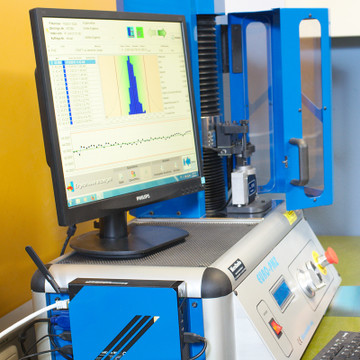

- Statistical processing of the measured values to control production

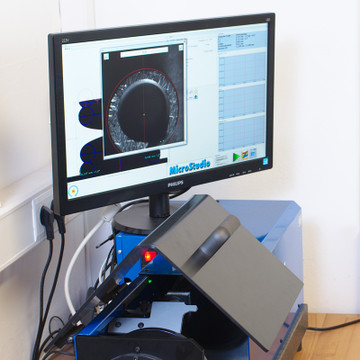

- Support of modern, monitored means of measurement

Among the test devices employed by us are:

- Electronic test scales

- Torsion meters

- Profile projectors

- Optoelectronic measuring systems

- Raw material testing machines

- Thickness measuring devices (X-ray fluorescence)

- Instruments for electrical resistors

- Endurance tests

Thanks to faster information systems, we are able to directly influence the production process. Vulnerabilities can be identified in the approach and preventive measures undertaken in a timely manner.

The fact that we are recognized by customers in many industries as a "Qualified Supplier" and are classified as an A-supplier is evidence of our high standards. We see this as our duty - and challenge for the future.